Manufacturing Process

- Slitting

- Tube Forming and Welding

- Annealing

- Cutting

- Pickling

- Straightening

- Tube Draw

- End Finish

- Polishing

- Destructive Testing

- Eddy Current Testing

- Dispatch

- Packing

- Final Inspection

- Hydro Testing

The various processes involved in the manufacturing of welded tubes are:

Slitting

Tube Forming and Welding

Annealing

Cold drawing or Sizing

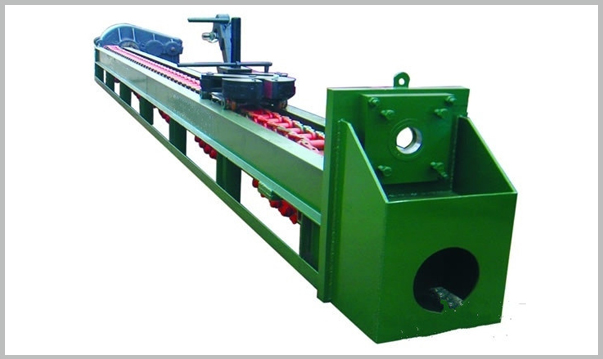

Straightening

Pickling

Cutting and End Finish

Tube Laser Cutting

Polishing

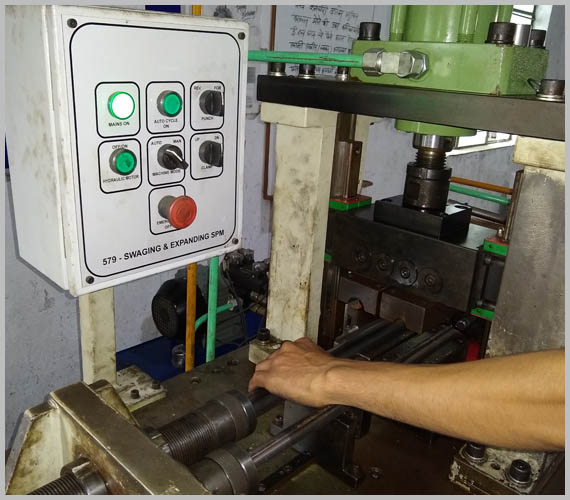

Swaging and Expansion